Side Table / Stool

Materials + Supplies:

• Rubber Gloves, Safety Glasses, Dust Mask

• 10" Concrete Form Tube

• Shelf Liner

• Spray Adhesive

• 11"x11" Plastic Sheet

• Base Surface

• Duct Tape

• Mixing Containers

• 25 lbs. ShapeCrete

Tools:

• Hand Saw

• Utility Knife

• Ruler / Square

• Hot Glue Gun

• 100% Silicone Caulk and Caulking Gun

• CHENG Corner and Seam Shaping Tool

• Razor Blade

• Trowel

• Diamond Hand Sanding Pad

Size: 18" x 10"

Color: Grey and Blue

Technique: Hand Packed

Side Table / Stool

A concrete form tube is almost all you need to make this side stool. The finished piece is hollow and weighs about 20-25 lbs. depending on the thickness.

Step 1: Cut Down Concrete Form Tube

- Measure down the form tube and make marks with a pen at 18".

- Tape around the tube to connect the marks. The tape will act as a guide, making it easier to cut the tube straight.

- Cut the tube to size with a hand saw, utility knife, or band saw.

Step 2: Glue Shelf Liner in Place

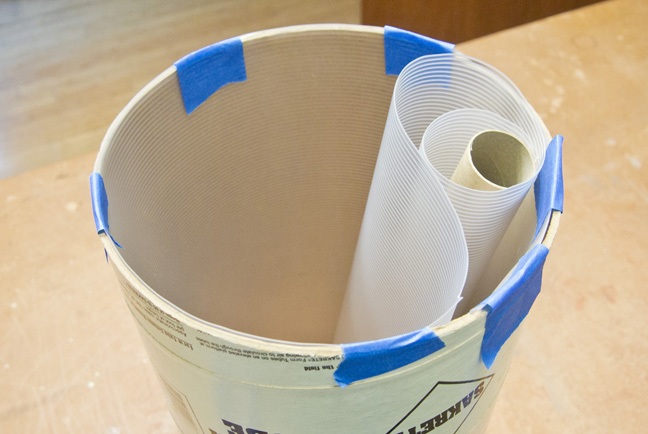

This is the trickiest part of the project, but it's optional. Gluing a plastic shelf liner inside the tube will give the finished piece a texture. The shelf liner here is just over 18" in width, so it fits perfectly inside the 18" tall form tube.

- Tape the shelf liner in place, working your way around the inside of the tube and making sure that the liner is tight against the inside.

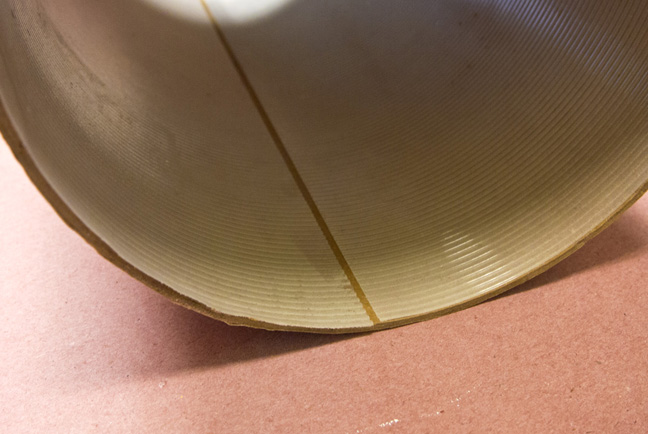

- Make a mark on the liner where it meets the starting point.

- Cut the liner to length with a utility knife, using a ruler as a guide.

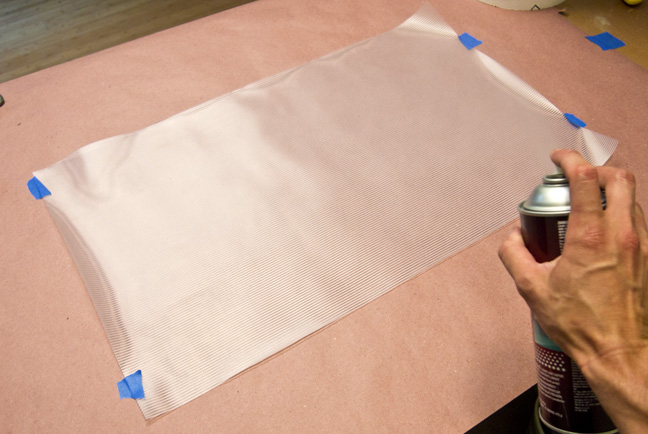

- Lay down some contact paper and spray the non-textured side of the shelf liner with spray adhesive. Follow the directions on the adhesive and spray the interior of the tube, then wait 5-10 minutes for the adhesive to get tacky.

- Carefully place the liner inside the tube and press it into place.

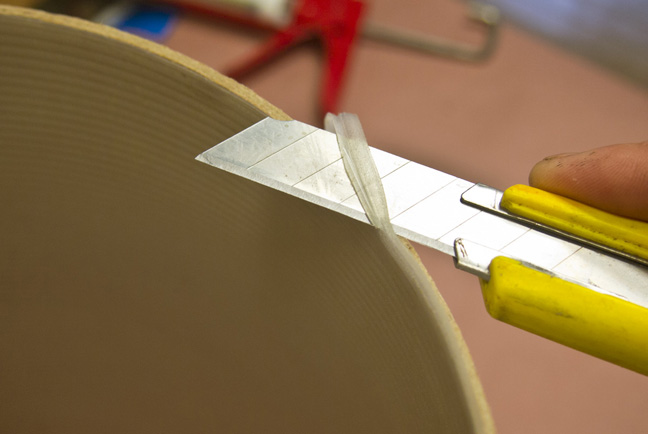

- Trim away excess with a utility knife.

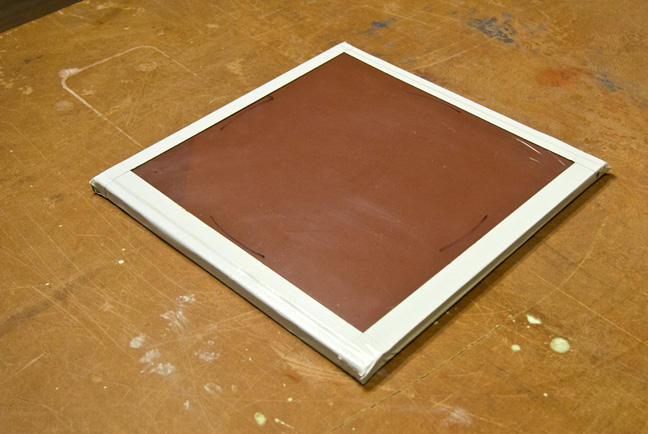

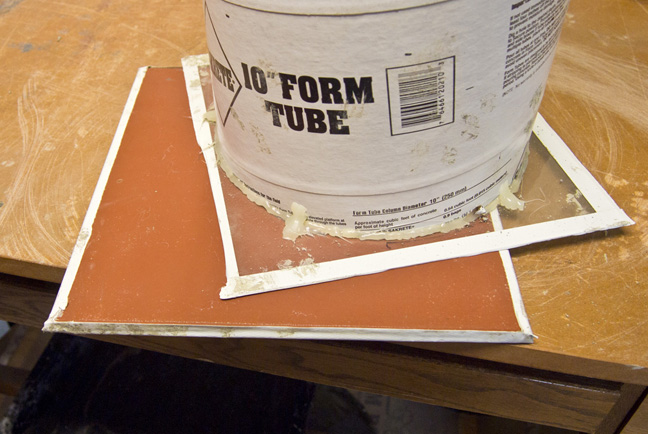

Step 3: Make the Base and Glue Down the Tube

Make the base for the form tube using something flat, like a scrap piece of plywood, or in this case, a terracotta tile that was laying around. Tape a piece of plastic (11"x11") to the tile. The plastic will make it easy to remove from the piece later.

- Tape the plastic down on the tile.

- Place the form tube in the center of the tile.

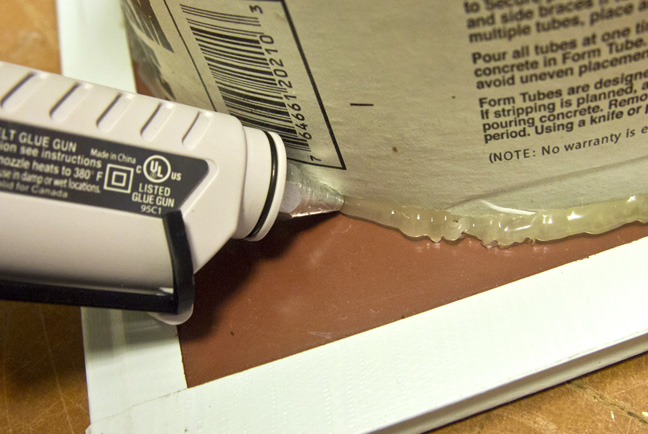

-

Run a bead of hot glue around the base of the form tube to hold it in place.

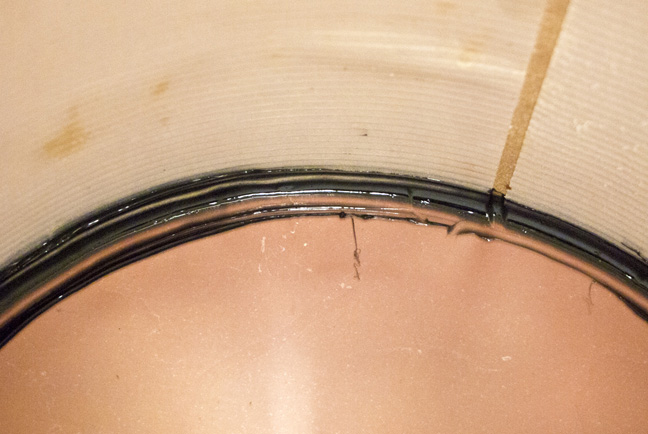

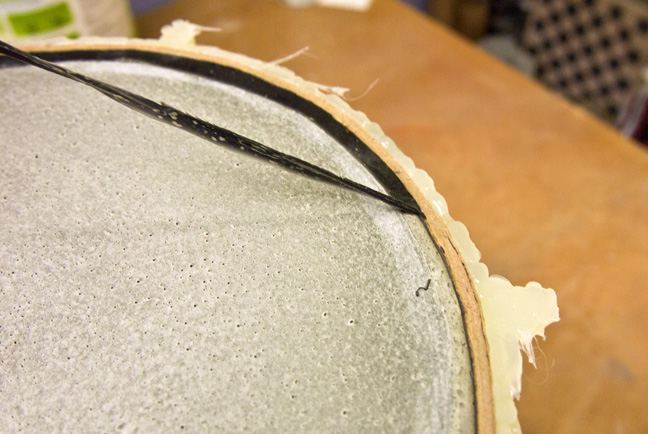

Step 4: Silicone the Inside Edge

This step is also optional, but it will create a nice round-over on the top edge. If you skip this step, the top will have some sharp edges that need to be sanded down with diamond hand pads.

- Run a bead of caulk around the bottom inside edge of the tube.

- Tool the caulk with a seam shaping tool (an acrylic rod cut at an angle).

- Scrape up the excess silicone with a razor blade.

- Wait for the silicone to cure and then pull up the excess silicone from the sides of the tube.

- After the silicone has fully cured, clean out the form with denatured alcohol.

Now the form is ready to pack.

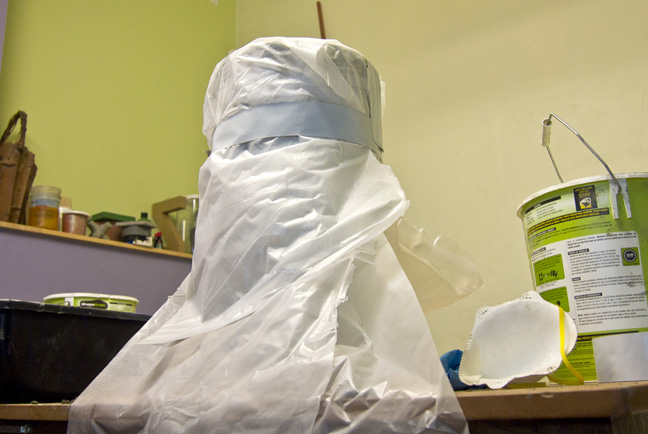

Step 5: Mix ShapeCrete

A project this size will take about 25 lbs. of mix, at about 5/8" - 3/4" thick. It helps to mix this amount in a 5-gallon bucket or a concrete mixing tub.

Mix ShapeCrete to a Clay-Like Consistency.

- Add half the water to the tub.

- Add the dry mix with the dry pigment already blended in (optional).

- Blend thoroughly by hand or with a paddle mixer. The mix should hang vertically when it's the right consistency. Adjust water content as needed.

Always wear a rubber gloves, safety glasses, and a dust mask when mixing.

Step 6: Pack the Form

- Begin by packing the bottom of the form to an even thickness. Press the mix into the edges of the form so you don't leave air bubbles.

-

Gradually pack the mix up the walls of the form, turning it as you go along.

-

If the mix is slumping down, it may be too wet. Try pressing thinner pads into the form and then coming back with a second layer to thicken it up.

-

When you get to the top of the form, smooth the top edge with a trowel or putty knife.

Cover with plastic and let it cure for 24-48 hours before removing it from the form.

Step 7: Demold

Stripping the form is easy.

- Remove the tape from the tile so the plastic is loose.

- Flip the piece over and peel away the plastic.

- Use a utility knife to carefully slice into the tube and gradually peel it away. Be careful not to cut too deep into the piece.

- Sand any jagged edges with diamond hand pads, files, or coarse sandpaper.

The Finished Piece:

Concrete form tubes are really versatile and come in a huge range of sizes so they can be used to make a lot of different (cylindrical) things. The tubes can be packed to form planters, waste bin surrounds, small containers, or short side tables like this project.